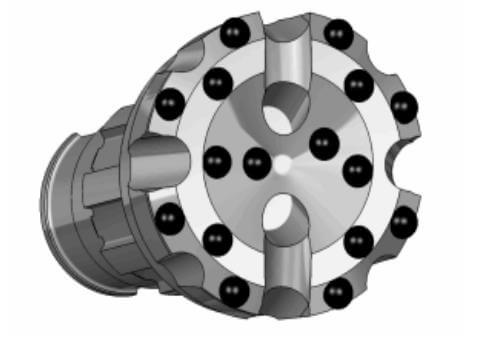

This bit face is specifically for medium hard and homogeneous rock formations. Good hole deviation control and good flushing capacity.

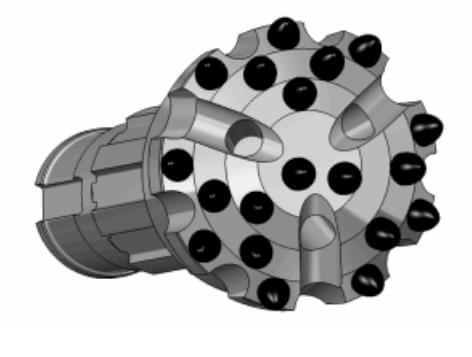

This face is for high penetration rates in soft to medium-hard with low to medium air pressure. It is the most resistance to bit body, and may reduce the load and wear on gauge inserts, but poor hole deviation control.

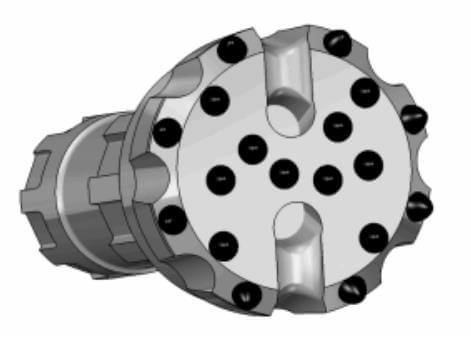

This kind of face sharp is suitable for hard to very hard and abrasive rock formations in applications with high air pressures. Good penetration rates a resistance to bit body.

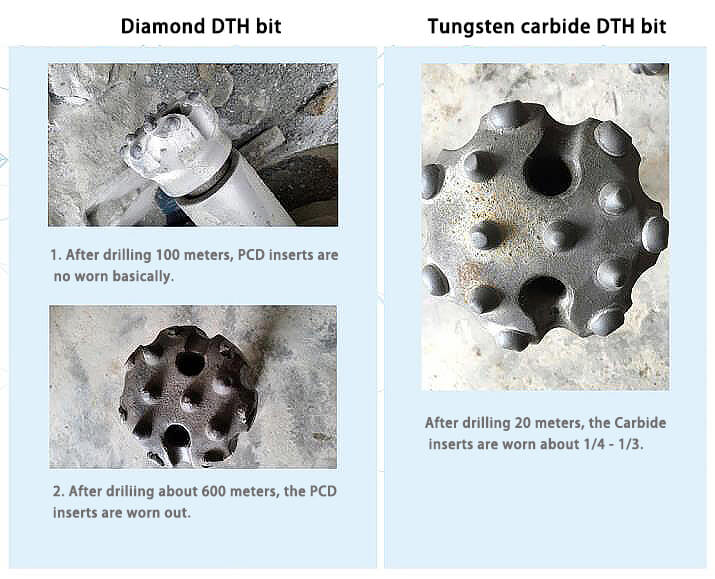

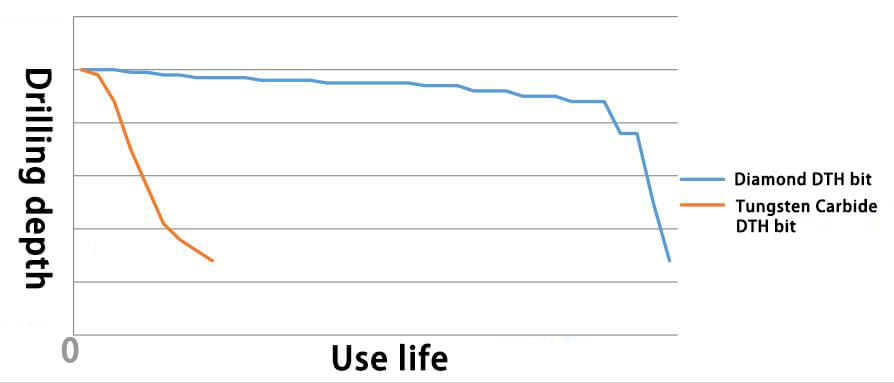

1. The service life of the Diamond DTH Bit is increased by more than 6 times;

2. The overall tool cost of the operation decreased by more than 30%;

3. The production efficiency of the operation is increased by more than 20%;

4. It can better maintain the quality of the well hole;

5. Make the target application that was impossible to complete once become possible;

6. Reduce the frequency of tool replacement and reduce the labour intensity of workers.

|

Shank style |

Diameter in mm |

NO. Air Holes |

Gauge PDC Buttons |

Front PDC Buttons |

Approx. weight |

Part number |

|

DHD3.5 |

85 |

2 |

6*φ13 |

4*φ12 |

5.0 kg |

DHD3.5-85 |

|

90 |

2 |

6*φ14 |

4*φ12 |

5.8 kg |

DHD3.5-90 |

|

|

95 |

2 |

6*φ14 |

5*φ12 |

5.9 kg |

DHD3.5-95 |

|

|

100 |

2 |

6*φ14 |

6*φ12 |

6.1 kg |

DHD3.5-100 |

|

|

105 |

2 |

8*φ13 |

6*φ12 |

6.3 kg |

DHD3.5-105 |

|

|

DHD340 |

105 |

2 |

6*φ14 |

5*φ13 |

8.6 kg |

DHD340 -105 |

|

110 |

2 |

7*φ14 |

6*φ13 |

8.8 kg |

DHD340-110 |

|

|

115 |

2 |

7*φ14 |

7*φ13 |

9.0 kg |

DHD340-115 |

|

|

120 |

2 |

8*φ14 |

7*φ13 |

9.5 kg |

DHD340-120 |

|

|

127 |

2 |

8*φ14 |

7*φ14 |

9.9 kg |

DHD340-127 |

|

|

DHD350 |

133 |

2 |

7*φ16 |

7*φ14 |

15.0 kg |

DHD350-135 |

|

140 |

2 |

7*φ19 |

7*φ14 |

16.5 kg |

DHD350-140 |

|

|

146 |

2 |

8*φ19 |

7*φ14 |

17.0 kg |

DHD350-146 |

|

|

152 |

2 |

8*φ19 |

8*φ14 |

17.8 kg |

DHD350-152 |

|

|

165 |

2 |

8*φ19 |

8*φ16 |

18.5 kg |

DHD350-165 |

|

|

DHD360 |

152 |

2 |

8*φ19 |

8*φ16 |

23.3 kg |

DHD360-152 |

|

165 |

2 |

8*φ19 |

8*φ16 |

25.2 kg |

DHD360-165 |

|

|

171 |

2 |

8*φ19 |

10*φ16 |

25.8 kg |

DHD360-171 |

|

|

190 |

2 |

10*φ19 |

12*φ16 |

28.5 kg |

DHD360-190 |

|

|

203 |

2 |

10*φ19 |

14*φ16 |

29.5 kg |

DHD360-203 |

|

|

DHD380 |

203 |

2 |

10*φ19 |

14*φ16 |

48.1 kg |

DHD380-203 |

|

216 |

2 |

10*φ19 |

14*φ16 |

52.0 kg |

DHD380-216 |

|

|

241 |

2 |

12*φ19 |

18*φ16 |

58.7 kg |

DHD380-241 |

|

|

254 |

2 |

12*φ19 |

21*φ16 |

60.4 kg |

DHD380-254 |

|

|

292 |

2 |

12*φ19 |

21*φ16 |

80.1 kg |

DHD380-292 |

Inquiry :