.png)

.png)

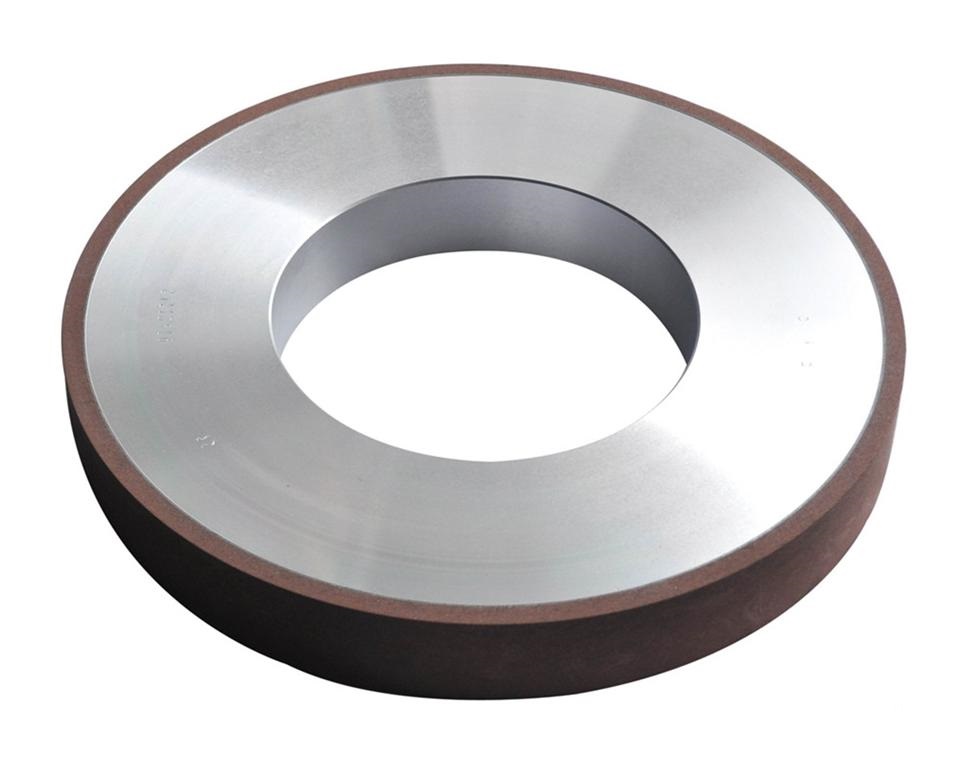

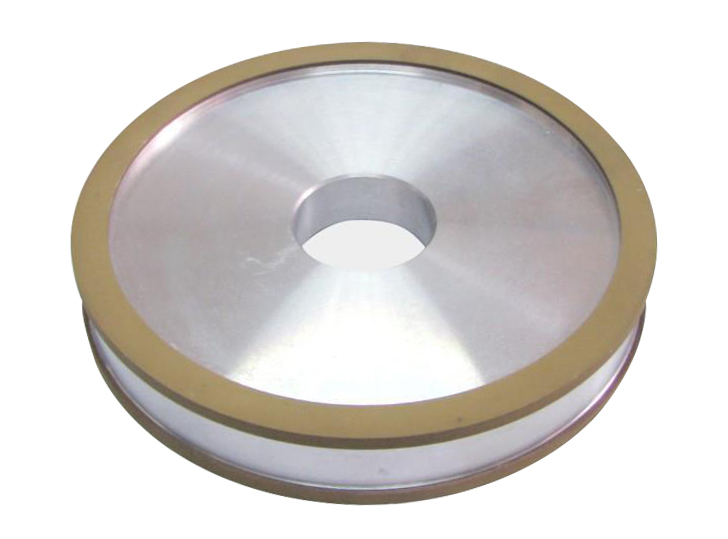

Grinding wheels for carbide - Resin bond diamond grinding wheel

Feature:

1.Good self sharpness.

2.Sharp cutting.

3.High grinding efficiency.

4.Easy to trim.

5.Great surface finish for processing workpieces.

Application: It is widely used in accurately grinding ceramic, glass, cemented carbide, hard alloy steel, etc.

| D | T | X | H | Con | Grits Size |

| mm | mm | mm | mm | % | D151 D126 D107 D91 D76 D64 D54 D46 |

| 50 | 0.8-20 | 3-20 | 16-25.4 | 50%-150% | |

| 75 | 0.8-20 | 3-20 | 22.23-25.4 | 50%-150% | |

| 100 | 3- 12 | 10-20 | 22.23-25.4 | 50%-150% | |

| 125 | 3-15 | 10-20 | 22.23-25.4 | 50%-150% | |

| 150 | 3-20 | 10-25 | 22.23-25.4 | 50%-150% | |

| 175 | 6-20 | 10-25 | 22.23-25.4 | 50%-150% | |

| 200 | 23-20 | 10-25 | 22.23-25.4 | 50%-150% | |

| 250 | 6-25 | 10-30 | 22.23-25.4 | 50%-150% | |

| 300 | 6-25 | 10-30 | 22.23-25.4 | 50%-150% | |

| 350 | 10-25 | 10-30 | 22.23-25.4 | 50%-150% | |

| 400 | 6-30 | 20-35 | 22.23-25.4 | 50%-150% | |

| 450 | 6-30 | 20-25 | 22.23-25.4 | 50%-150% | |

| 500 | 10-30 | 20-35 | 22.23-25.4 | 50%-150% | |

| 600 | 20-30 | 25-35 | 22.23-52.0 | 50%-150% | |

| other size are upon requirement | |||||

| D | T | X | H | Con | Grits Size |

| mm | mm | mm | mm | % | D151 D126 D107 D91 D76 D64 D54 D46 |

| 50 | 0.8-20 | 3-20 | 16-25.4 | 50%-150% | |

| 75 | 0.8-20 | 3-20 | 22.23-25.4 | 50%-150% | |

| 100 | 3- 12 | 10-20 | 22.23-25.4 | 50%-150% | |

| 125 | 3-15 | 10-20 | 22.23-25.4 | 50%-150% | |

| 150 | 3-20 | 10-25 | 22.23-25.4 | 50%-150% | |

| 175 | 6-20 | 10-25 | 22.23-25.4 | 50%-150% | |

| 200 | 23-20 | 10-25 | 22.23-25.4 | 50%-150% | |

| 250 | 6-25 | 10-30 | 22.23-25.4 | 50%-150% | |

| 300 | 6-25 | 10-30 | 22.23-25.4 | 50%-150% | |

| 350 | 10-25 | 10-30 | 22.23-25.4 | 50%-150% | |

| 400 | 6-30 | 20-35 | 22.23-25.4 | 50%-150% | |

| 450 | 6-30 | 20-25 | 22.23-25.4 | 50%-150% | |

| 500 | 10-30 | 20-35 | 22.23-25.4 | 50%-150% | |

| 600 | 20-30 | 25-35 | 22.23-52.0 | 50%-150% | |

| other size are upon requirement | |||||

Inquiry :