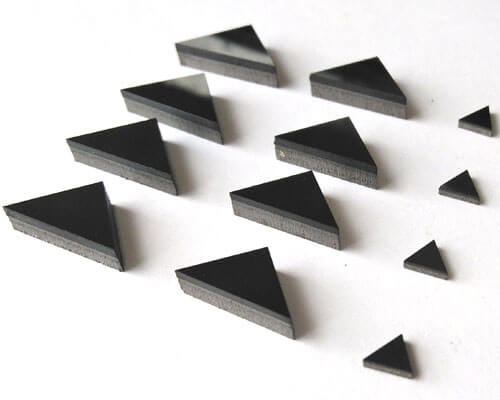

Diameter: 48mm, 54mm, 60mm, 70mm

Thickness: 1.6mm, 2.0mm, 3.2mm

Grain size: Fine, medium, coarse — chosen based on cutting requirements.

| Grade | Grain size | Bond | Feature | Application |

| 3BD510 | 10μm | Metal | General PCD grade, with high impact resistance and high wear resistance | Wood, graphite, stone, metal, etc. |

| 3BD512W | 10μm | Metal | General PCD grade, with good EDM cutting performance, high wear resistance and high impact resistance | Wood, plastic board, graphite, ceramic, metal, etc. |

| 3BD605 | 5μm | Metal | Excellent wire EDM and mechanical cutting performance with high impact resistance and high wear resistance | Low silicon aluminum alloy, wood, plastic, metal, etc. |

| 3BD612 | 10μm | Metal | General PCD grade, with high impact resistance and very high wear resistance | Middle silicon aluminum alloy, metal composite materials, ceramic, plexiglass, graphite, metal, etc. |

| 3BD632 | 2~30μm | Metal | Excellent wear resistance, high thermal stability and high impact resistance through adopting mixed grains | High silicon aluminum alloy, composite plastics, bimetal, metal composite materials, ceramic, etc. |

| Grade | Grain size | Bond | Feature | Application |

| 3BD510 | 10μm | Metal | General PCD grade, with high impact resistance and high wear resistance | Wood, graphite, stone, metal, etc. |

| 3BD512W | 10μm | Metal | General PCD grade, with good EDM cutting performance, high wear resistance and high impact resistance | Wood, plastic board, graphite, ceramic, metal, etc. |

| 3BD605 | 5μm | Metal | Excellent wire EDM and mechanical cutting performance with high impact resistance and high wear resistance | Low silicon aluminum alloy, wood, plastic, metal, etc. |

| 3BD612 | 10μm | Metal | General PCD grade, with high impact resistance and very high wear resistance | Middle silicon aluminum alloy, metal composite materials, ceramic, plexiglass, graphite, metal, etc. |

| 3BD632 | 2~30μm | Metal | Excellent wear resistance, high thermal stability and high impact resistance through adopting mixed grains | High silicon aluminum alloy, composite plastics, bimetal, metal composite materials, ceramic, etc. |

Inquiry :