The diamond wire saw is a flexible cutting tool. Its working principle is to use a rope to saw through wood. So if there is a rope that is harder than stone and concrete, can it complete the cutting of stone and concrete? Since the 1960s, this idea has been continuously verified. First, in 1968, the British used spiral steel wires coated with diamonds to cut soft marble. Then this technology was adopted by Italy in the 1970s. People continued to develop and eventually formed the diamond wire saw.

Since the 1990s, wire saws whose concept was proposed no more than 30 years ago have begun to enter China. With the efforts of the previous generation of scientific researchers and technicians, my country's diamond wire saw technology has experienced continuous development for nearly 30 years. By 2021, China will become the largest producer and exporter of diamond wire saws in the world, with an annual output of more than 15 million meters.

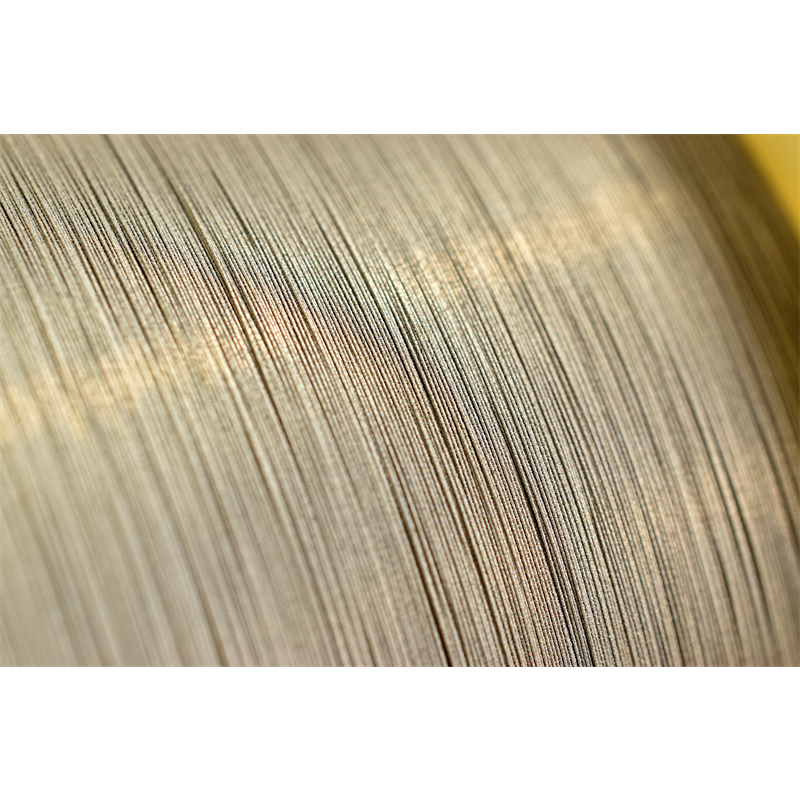

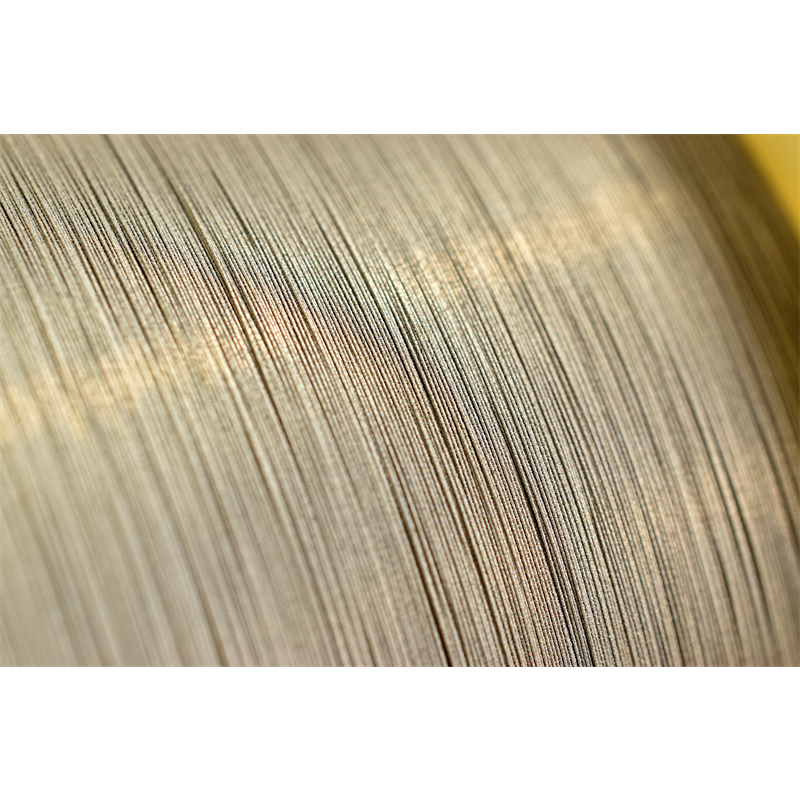

The diamond wire saw mainly uses a flexible steel wire rope with a length of 50 meters or 100 meters. This wire rope has strong tensile resistance and is not easy to break. The wire rope increases the tension value through continuous winding. On the outside of the wire rope, at the same distance, The formed annular diamond beads are fixed in position through rubber, plastic, spring and other materials. The final diamond wire saw consists of three parts: steel wire rope, beads, and connecting material. The final product is called a diamond wire saw.

The main cutting objects of the diamond wire saw are hard materials. The soft cutting objects are applied with powerful garbage, so that the soft rope has strong tensile force. Through these tensile forces, the beaded diamonds on the entire wire saw can be quickly Grind the cutting material to finalize the cut.

With the development of science and technology, diamond wire saws are still in a stage of rapid development. In terms of lifespan and efficiency, the current diamond wire saws have been able to cut hundreds of square meters of hard steel-mixed materials from the earliest cutting of soft stones. , but in just 20 years, the improvement of wire rope technology, the development of glue injection technology and the innovation of artificial diamond technology have led to the rapid development of diamond wire saws.

At present, the diamond wire saws made in China have gradually matured in mining, especially rubber ropes, especially steel-concrete cutting wire saws. As far as Somebetter Diamond's wire saws are concerned, they have the ability to cut large surfaces. In terms of efficiency and lifespan, it is also close to the first-tier foreign brands. However, in terms of combined wire saws for cutting block materials, in order to better save cutting materials, the thickness of beads has gradually become thinner, from the early diameter of 8.8mm, 7.2mm, 6.5mm to the current 5.3mm. Even some companies have already It can produce 4.2mm wire wire saws, but the thinnest diamond wire saws are wire saws. The thinnest wire saws are only 2.4mm, which can further save stone materials and make the utilization rate of stone materials higher.

-tuya.jpg)

When the diamond wire saw is developed to its extreme, it will form a wire saw. By coating diamond on the wire rope, the wire saw is very thin, so the cutting efficiency and cutting surface are greatly reduced. In addition to saving cutting materials, it also improves the cutting capacity and the smoothness of the cutting surface. The precision has also been greatly improved. Currently, this product is widely used in jade cutting, agate and precious crystal cutting. In the future, with the development of science and technology, I believe that this special wire saw, the diamond wire saw, can play a greater role. .

-tuya.jpg)