A.The wire drawing Die is often caused by the quality of the drawing die itself.

(1) the insert of the wire drawing die blank and the steel sleeve of the die is asymmetric, and the distribution of the steel sleeve of the insert hard alloy is uneven or has gaps, which are easy to cause u-shaped cracks in the process of drawing the wire rod;

(2) in the laser drilling process of diamond mold blank, poor cleaning of sintering marks or uneven heating will lead to a pile of metal catalysts and binders in the diamond layer, which will easily lead to pits in the die during the wire drawing process;

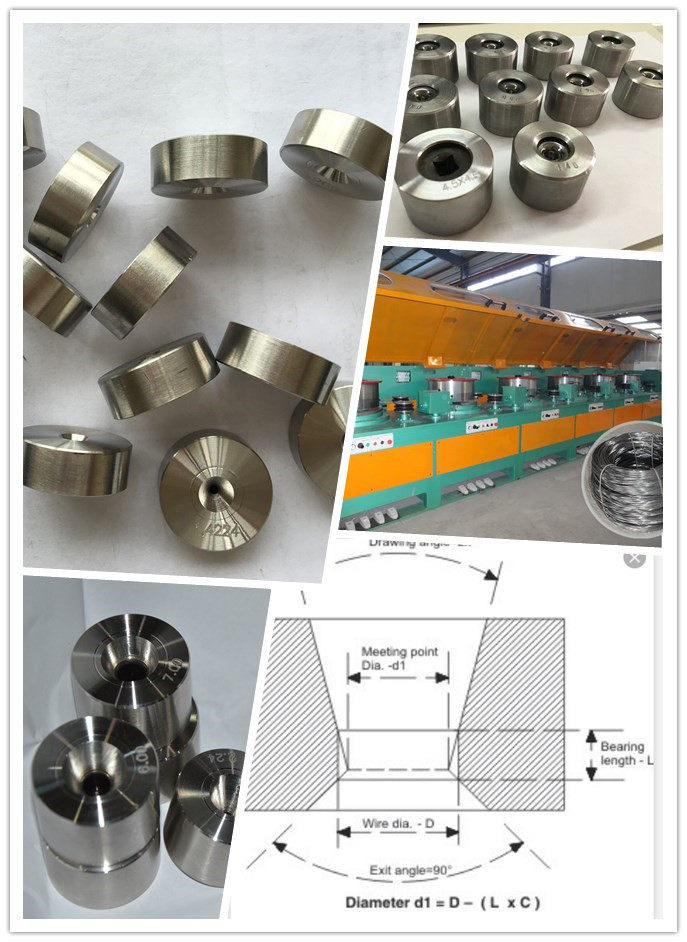

(3) the mold hole design is unreasonable, the opening of the inlet lubrication area is too small, the molding area is too long, which will lead to poor lubrication, resulting in mold wear and tear or even fragmentation.

B.Improper use of wire drawing process leads to rapid wear and tear of the mold.

(1) excessive shrinkage of the drawing surface leads to cracks or breakage of the mold.Cracks or fracture cracks are mostly caused by internal stress release.Exist in any material structure, the internal stress is inevitable, drawing wire which is caused by internal stress could enhance the mold structure of microcrystalline, but when drawing surface shrinkage is too big, can't timely lubrication and temperature rise is too gao will cause mould show that part of the material being removed and microcrystalline structure on the stress is increased greatly, making it easier to produce cracks or breakage.

(2) the tension axis of the wire rod is not symmetric with the center line of the mold hole, resulting in uneven stress effect on the wire rod and the drawing die. The impact of mechanical vibration will also cause a high stress peak on the wire rod and the drawing die, both of which will accelerate the wear of the die.

(3) uneven hardness of wire rod and other factors caused by uneven annealing are likely to cause premature fatigue damage to diamond wire drawing dies, forming ring grooves and aggravating wear and tear of mold holes.

(4) the wire surface is rough, and the surface adheres to oxide layer, sand or other impurities, etc., which will cause the mold to wear out too quickly.When the wire passes through the die hole, the hard, brittle oxide layer and other adhesion impurities will cause the die hole to wear and scratch the wire surface as quickly as abrasive.

(5) poor lubrication or metal debris impurities in lubricating oil cause mold wear.Poor lubrication will make the surface temperature of the die hole rise too fast during wire drawing, diamond grains fall off, resulting in mold damage.It is very easy to scratch the surface of dies and wires when the lubricating oil is not clean, especially when it contains metal chips that fall off during drawing.