Advantages About Natural Diamond Wire Drawing Dies

| When drawing copper wire of the same diameter, the service life of polycrystalline diamond die is 300-500 times of that of carbide die, when drawing molybdenum wire, it is 80-100 times, when drawing nickel wire it is 50-80 times. |

|

While when drawing carbon steel, the service life of polycrystalline diamond die is 20-60 times of that of carbide die.

In addition to the wire drawing die of wire and cable commonly used, the polycrystalline diamond wire mould also includes enameled wire mould of motor, electric appliance and transformer, precision inner lead mould of integrated circuit and so on.

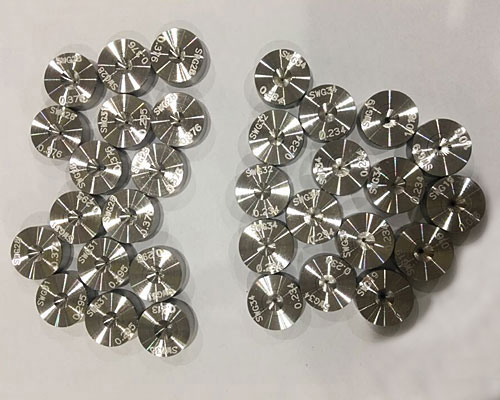

Yes, that's it ! Our PCD wire drawing dies, they are natural diamond dies or synthetic diamond single crystal and polycrystalline synthetic diamond. These dies are used in the drawing of low, medium and high carbon content wires and in the wire drawing of aluminum, copper and various alloys. PCD dies offer a high resistance to wear and an excellent wire surface finish. |

|