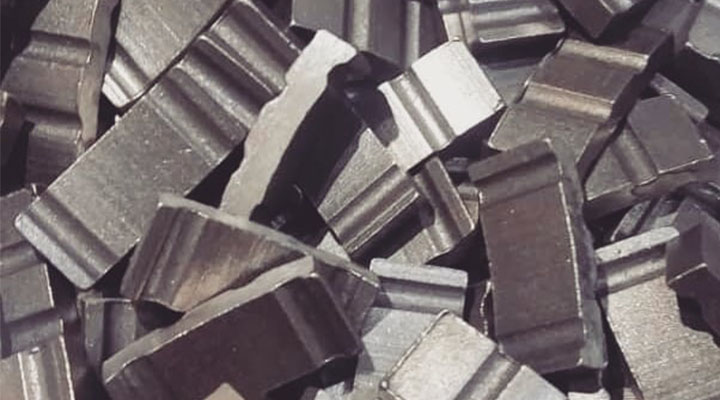

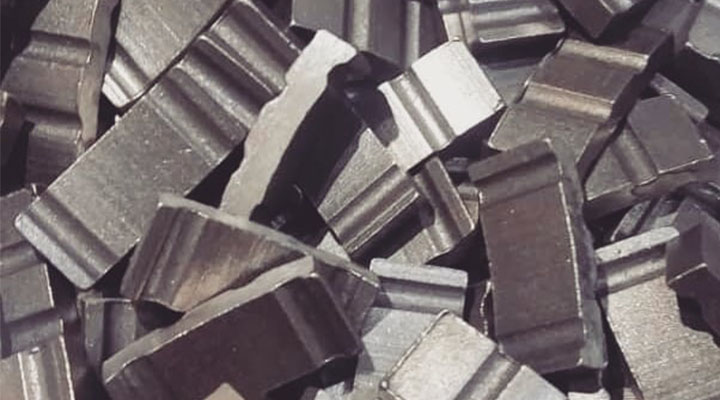

How to improve the sharpness and wear resistance of diamond segment

The sharpness and durability of the diamond segment are contradictory. If the carcass is less sharp than the wear-resistant saw blade, the carcass formula, sintering process, diamond strength, etc. will affect the sharpness of the diamond segment search. If the copper base is relatively better, Adding some fine material to the diamond will add sharpness.

This diamond has been developed as a raw material for many products for many years. When it can be synthesized by a certain temperature and pressure, the cutting tool is stepped into a period represented by superhard materials. Then if the cutter head is not well maintained, it will affect the service life and affect the work efficiency.

Through the continuous proportioning test and continuous market research feedback, in addition to the orderly distribution of diamond particle size, the wrapped diamond tool powder plays a vital role. The alloy powder series, pre-alloy powder series and elemental powder series have uniform particle size distribution, low oxygen content and small fluctuation range, and the self-sharpness of the tool is good, which fully satisfies the sharpness and wear resistance of the diamond tool bit.

Pre:Factors affecting the cutting life of diamond saw blades

Next:How to improve the binding force of the diamond segment body