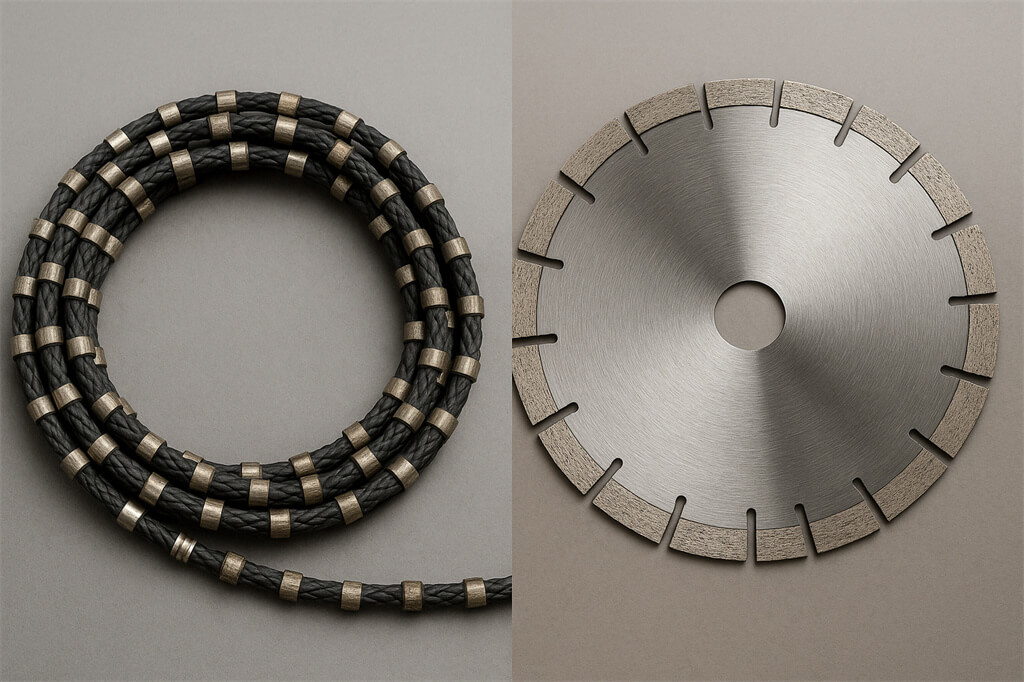

Diamond Wire Saw Rope vs. Diamond Segment Blades

In the stone processing and metal cutting industries, cutting efficiency and machining quality directly impact project costs and delivery schedules. Diamond wire saw rope and diamond segment blades are currently two mainstream cutting tools, each with its own structural characteristics and application scenarios. For purchasers, fully understanding the performance differences and economic applicability of these two tools is key to achieving accurate procurement and cost control.

This article will compare diamond wire saw rope and diamond segment blades in terms of performance, application differences, economic analysis, etc., to provide a reliable reference for your selection and procurement decisions.

Structure: Composed of steel wire rope, diamond beads, and rubber or elastic resin. The diamond beads are fixed onto the steel wire rope by electroplating or sintering.

Performance Features:

High-speed cutting capability, up to 20~35 m²/h;

Suitable for irregular cutting, especially in curved structures;

Small kerf (generally 6~8 mm), effectively reduces material loss;

High cooling efficiency, longer tool life when using water cooling.

Structure: Blade substrate with welded sintered diamond segments.

Performance Features:

High rigidity and stability, suitable for straight cutting;

Moderate cutting speed (typically 10~20 m²/h), but more stable;

Segment grit and composition customizable, suitable for different material hardness;

Limited cutting depth, requires multiple passes for thick materials.

Performance Summary Table:

|

Performance Metric |

Diamond Wire Saw Rope |

Diamond Segment Blades |

|

Cutting Speed |

High (20~35 m/h) |

Medium (10~20 m/h) |

|

Cutting Precision |

High (suitable for curves) |

Medium-High (for straight) |

|

Kerf Width |

6~8 mm |

8~12 mm |

|

Adaptability |

For large blocks, complex |

For medium/small regular shapes |

|

Material Waste |

Low |

Slightly higher |

Quarrying marble and granite;

Urban pier and concrete structure demolition;

Processing tombstones, columns, and other irregular stone;

Cutting precious metals like titanium alloy, zirconium alloy, etc.

Advantage: Suitable for large-scale or complex structural stone cutting, especially effective in vertical and deep cuts.

General cutting in stone processing plants;

Medium-hard materials like tiles, slate, sandstone;

Batch cutting of standard shapes like blocks and strips.

Advantage: Suitable for production lines and repetitive cutting structures, best paired with bridge cutting machines.

|

Tool Type |

Average Price (mid-range) |

Installation & Commissioning |

|

Diamond Wire Saw Rope |

High (200–400 RMB/m) |

High (requires special equipment) |

|

Diamond Segment Blades |

Medium (500–2000 RMB/pc) |

Low (general equipment) |

Diamond wire saw rope: Avg. life 25–35 m²/m;

Diamond segment blades: Each lasts ~500–1500 m².

Wire saw ropes are more sensitive to tension imbalance and uneven cooling, requiring periodic checks. Segment blades are easier to maintain — mainly blade replacement and balance adjustment.

Economic Summary:

|

Cost Metric |

Diamond Wire Saw Rope |

Diamond Segment Blades |

|

Initial Investment |

High |

Medium |

|

Cost per Area |

Medium |

Low–Medium |

|

Maintenance Cost |

Medium–High |

Low |

|

Project Suitability |

Large-scale projects |

Small-batch production |

For stone tool purchasers, choosing the right tool isn’t only about technical specs — it also depends on cutting material, production volume, and equipment compatibility. If your main focus is on quarrying and irregular cuts, diamond wire saw rope is recommended; for factories or contractors seeking flexibility and cost-effectiveness, diamond segment blades are more economical.

Also, the two tools are not substitutes but complements. For example, rough cutting with a wire saw followed by fine finishing with segment blades can improve overall efficiency.

Final Tip: Before purchasing, discuss material type, equipment compatibility, and batch size with your supplier to get customized recommendations and samples for the best price-performance ratio.

If you want to know moredetailed product parameters and price. You can send email to contact us. sales@3betterdiamond.com

Pre:Processing technology of PCD saw blades

Next:Back To List